expandable microspheres factory

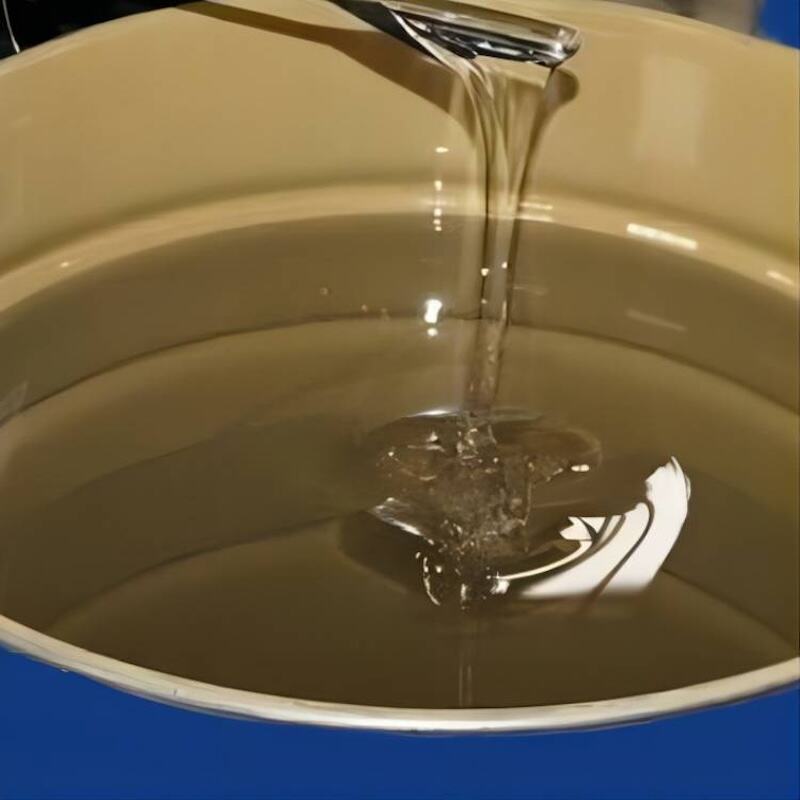

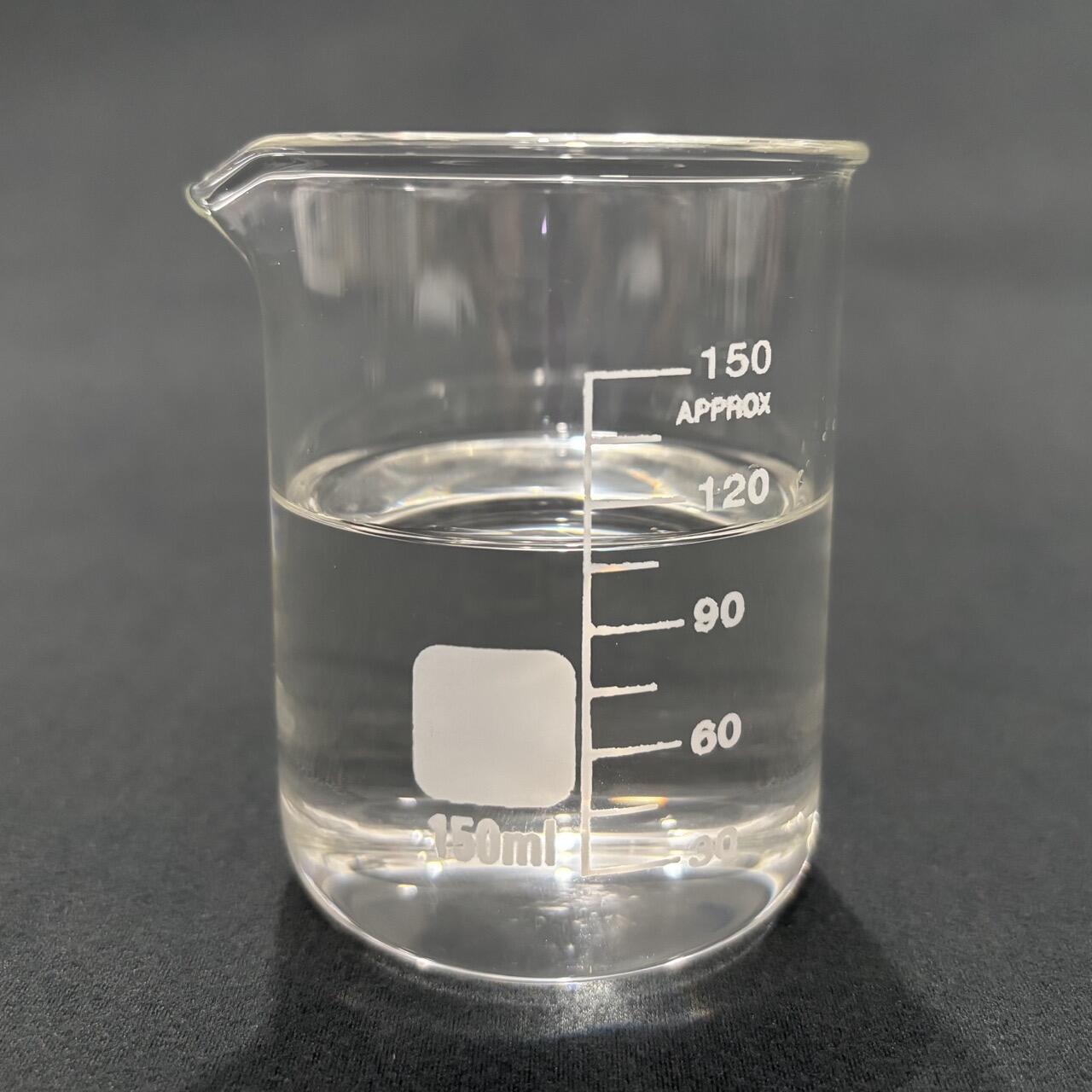

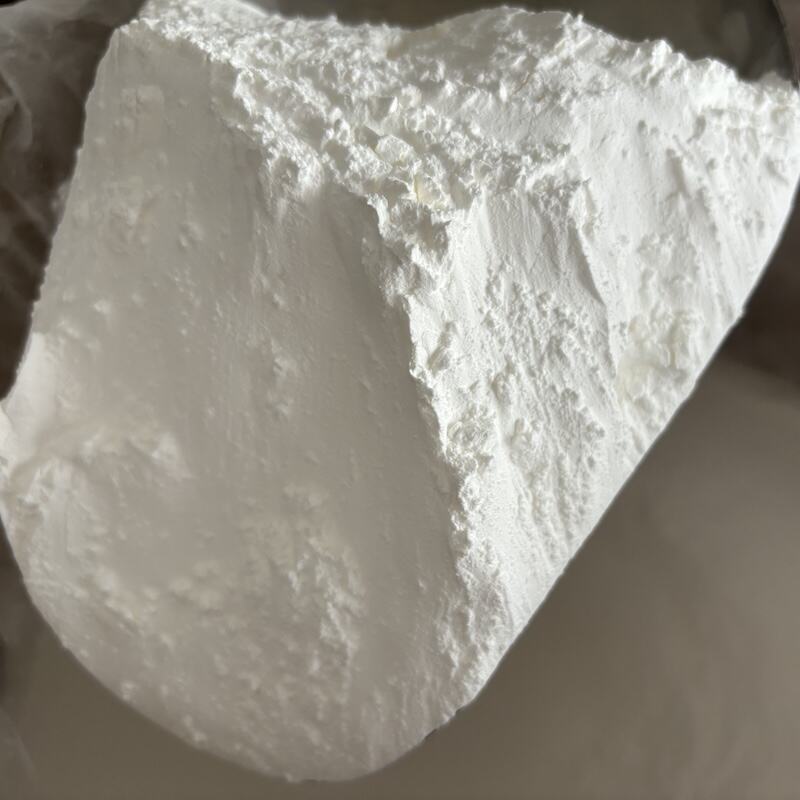

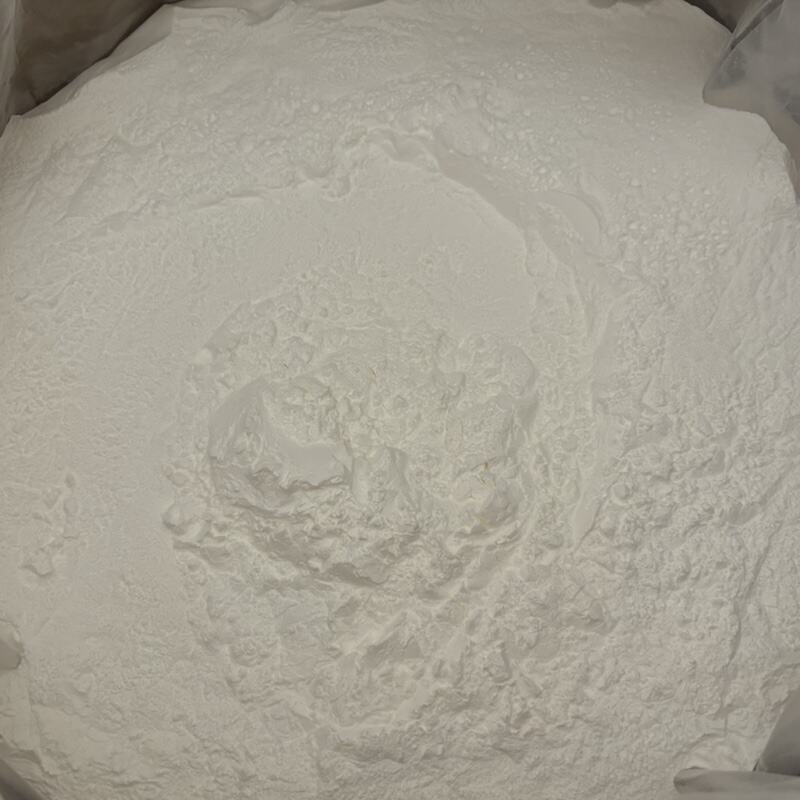

An expandable microspheres factory represents a state-of-the-art manufacturing facility dedicated to producing advanced polymer-based microspheres that expand when exposed to heat. These facilities incorporate cutting-edge production lines equipped with precise temperature control systems, specialized polymer processing units, and automated quality control mechanisms. The factory utilizes sophisticated polymerization technology to create microscopic spheres containing hydrocarbon gas, which expand dramatically when heated. The manufacturing process involves careful control of particle size distribution, shell thickness, and expansion characteristics. Modern facilities feature integrated research and development laboratories for continuous product innovation and quality assurance testing. The production area typically includes multiple reaction vessels, cooling systems, and advanced filtration equipment to ensure product purity. Environmental control systems maintain optimal conditions for consistent product quality, while automated packaging systems ensure efficient product handling and distribution. These facilities often implement sustainable manufacturing practices, including water recycling systems and energy-efficient operations. The factory's applications span various industries, from construction materials and automotive parts to packaging solutions and technical textiles. Quality control laboratories equipped with advanced analytical instruments ensure that each batch meets stringent specifications for expansion ratio, particle size, and thermal stability.