expandable microspheres

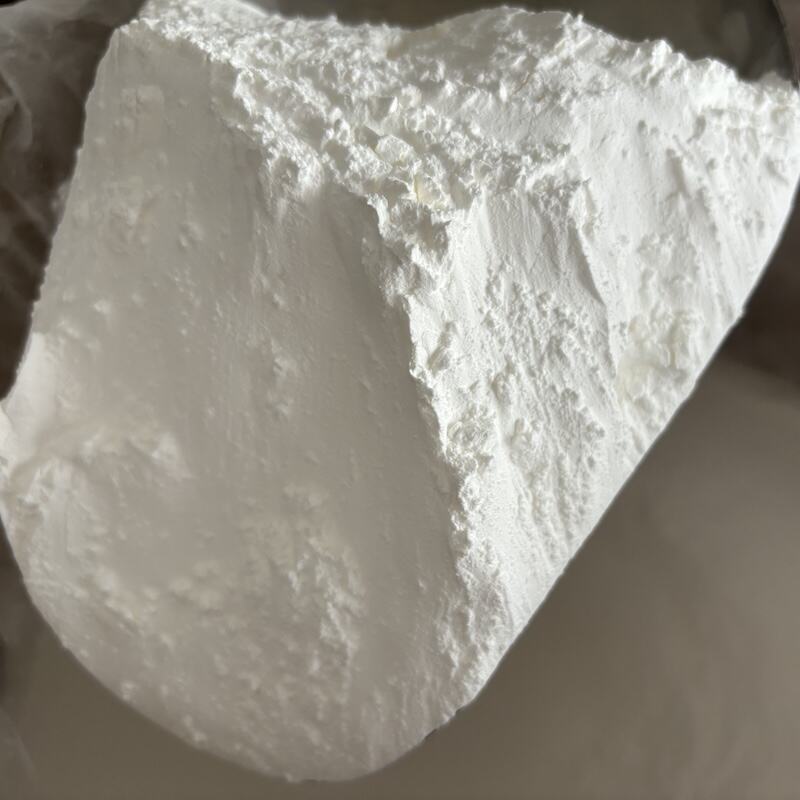

Expandable microspheres represent a groundbreaking advancement in material science technology, consisting of tiny thermoplastic spheres containing low-boiling-point hydrocarbons. When exposed to heat, these microscopic particles undergo a remarkable transformation, expanding up to 40 times their original size while maintaining their structural integrity. The shell of these spheres is made from specialized polymers that soften at specific temperatures, allowing the internal hydrocarbon to vaporize and create controlled expansion. This unique characteristic makes them invaluable in various industrial applications, from automotive manufacturing to construction materials. The spheres typically range from 10 to 40 microns in their unexpanded state and can reach sizes of up to 120 microns when fully expanded. Their controlled expansion process provides precise density reduction in materials, enabling manufacturers to achieve specific material properties. These microspheres have revolutionized product development by offering solutions for weight reduction, thermal insulation, and acoustic dampening. They are particularly valuable in creating lightweight composites, foams, and sealants that maintain structural stability while reducing overall material density. The technology behind expandable microspheres continues to evolve, with newer generations offering enhanced temperature resistance and improved expansion control.