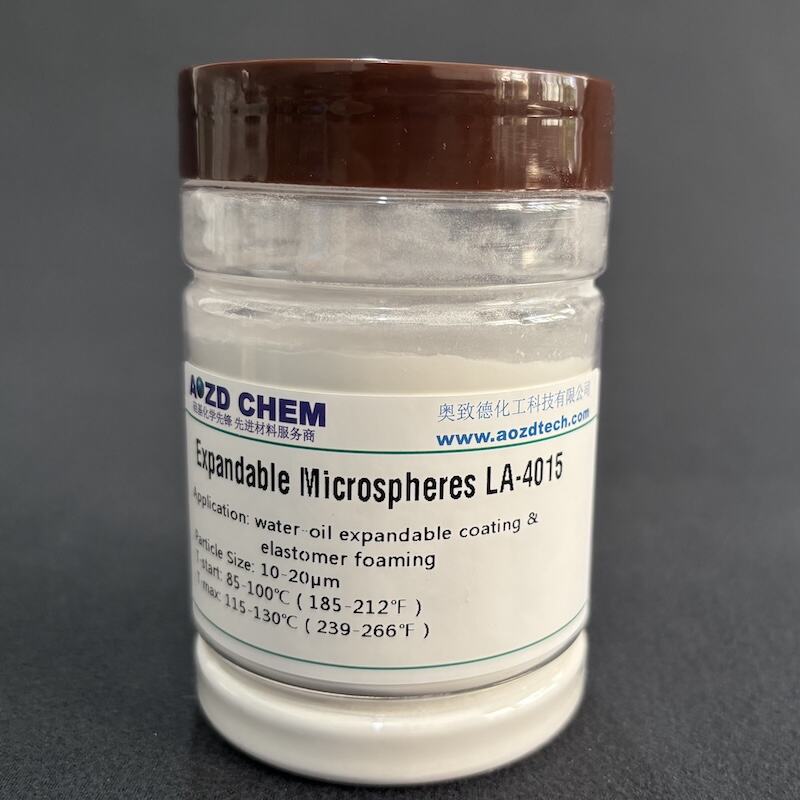

best expandable microspheres from china

Expandable microspheres from China represent a cutting-edge advancement in polymer technology, offering exceptional performance in various industrial applications. These innovative microspheres consist of a thermoplastic shell encapsulating a hydrocarbon blowing agent, which expands when exposed to heat. The microspheres typically range from 6 to 40 microns in diameter before expansion and can expand up to 60 times their original volume when heated. Chinese manufacturers have perfected the production process, ensuring consistent quality and reliable performance. These microspheres demonstrate remarkable stability under various processing conditions, maintaining their expanded form even after cooling. They excel in reducing density in numerous applications, including automotive parts, construction materials, and synthetic leather production. The technology behind these microspheres allows for precise control over expansion temperature ranges, typically between 80°C and 190°C, making them suitable for diverse manufacturing processes. Their closed-cell structure provides excellent insulation properties, while their lightweight nature contributes to significant material cost savings in end products. The microspheres also offer superior compression resistance and exceptional durability, making them ideal for demanding industrial applications.