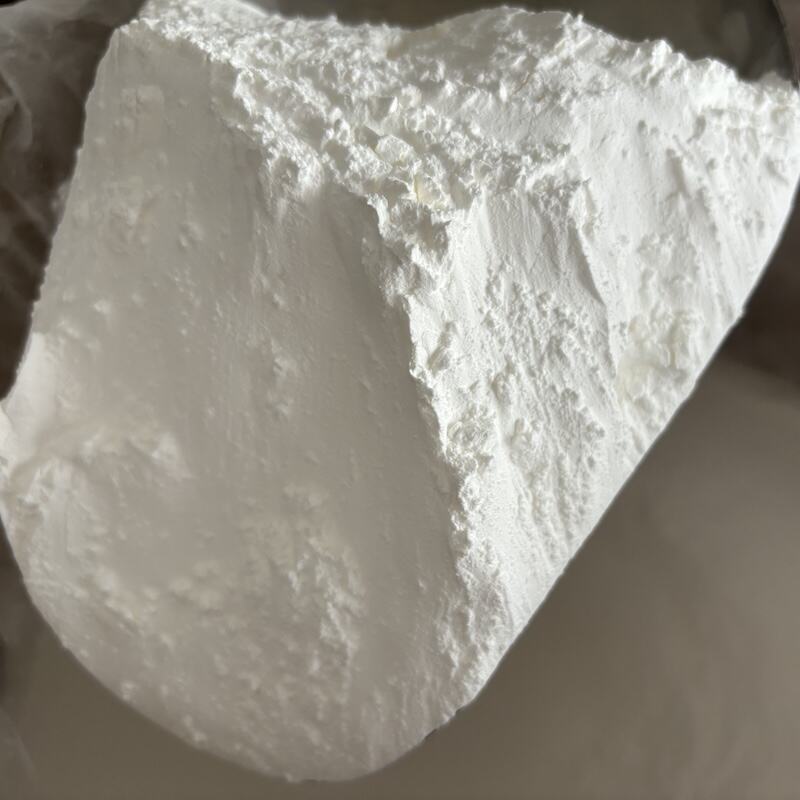

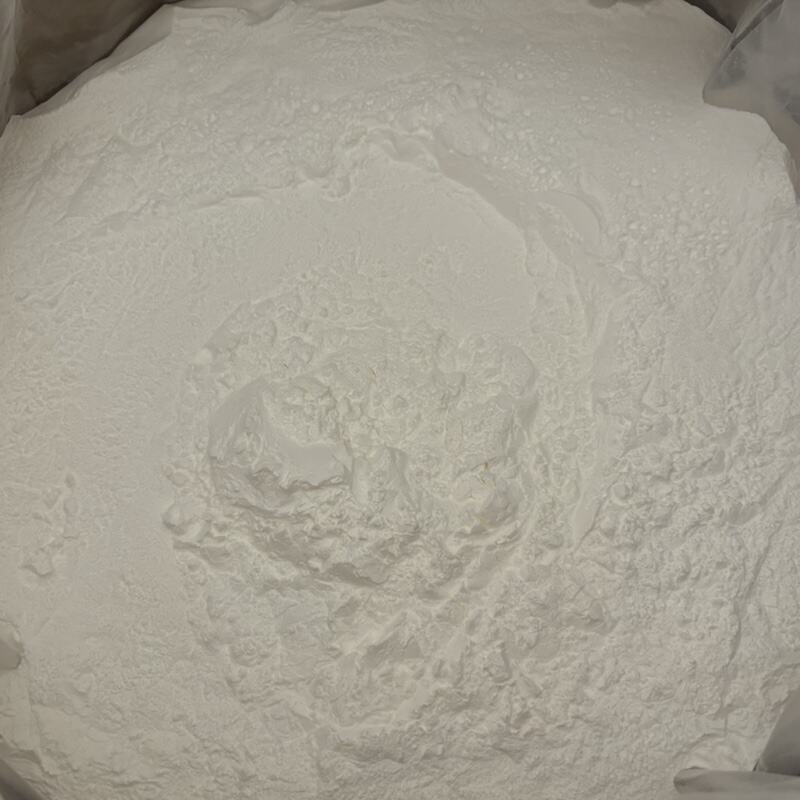

expandable microspheres for plastics

Expandable microspheres for plastics represent a revolutionary advancement in polymer technology, offering unique solutions for various manufacturing challenges. These microscopic spheres consist of a thermoplastic shell encapsulating a hydrocarbon blowing agent. When exposed to heat, these spheres undergo a controlled expansion process, increasing in size by up to 40 times their original volume while maintaining their spherical shape. This distinctive characteristic makes them invaluable in numerous plastic applications. The technology behind expandable microspheres enables manufacturers to achieve precise density reduction, improved surface quality, and enhanced material properties. These microspheres function as lightweight fillers, providing uniform cell structure and consistent density throughout the material. Their application spans across multiple industries, including automotive parts, packaging materials, synthetic leather, and construction materials. The spheres' ability to expand at specific temperature ranges allows for precise control over the final product's properties, making them particularly valuable in applications requiring exact specifications. Additionally, these microspheres contribute to significant weight reduction without compromising the structural integrity of the final product, making them an ideal choice for manufacturers seeking to optimize their material usage while maintaining product performance.