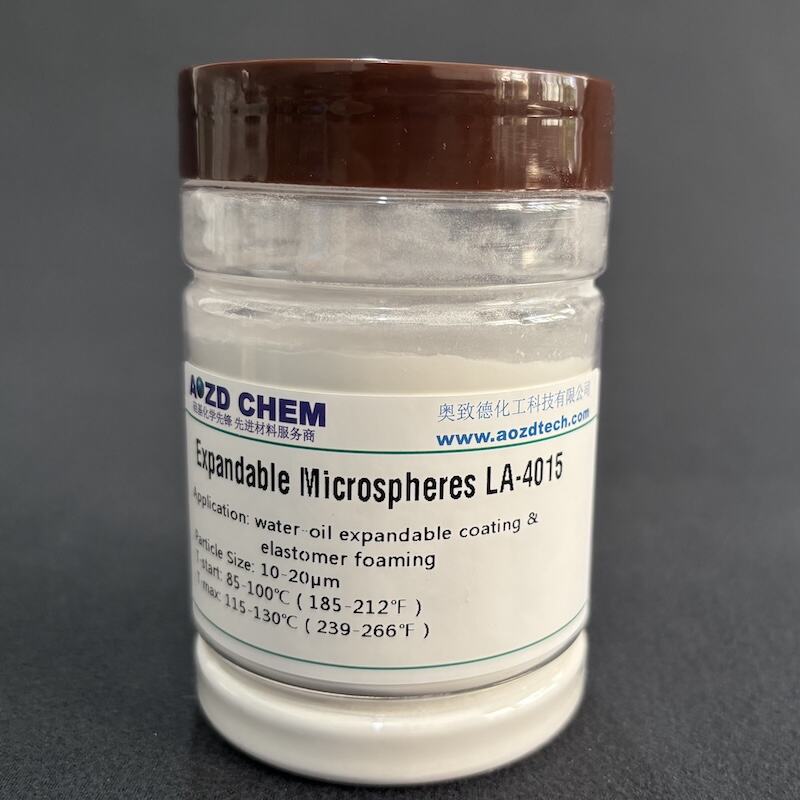

expandable microspheres for coatings

Expandable microspheres for coatings represent a groundbreaking innovation in surface treatment technology, offering unique capabilities that transform conventional coating applications. These microscopic spheres consist of a thermoplastic shell encapsulating a hydrocarbon blowing agent. When exposed to heat, these spheres undergo a remarkable expansion process, increasing in size by up to 40 times their original volume while maintaining minimal weight gain. This distinctive characteristic makes them invaluable in various coating applications, particularly where weight reduction and insulation properties are crucial. The technology behind expandable microspheres enables manufacturers to achieve superior surface textures, enhanced thermal insulation, and improved acoustic properties in their coating formulations. These microspheres integrate seamlessly into various coating systems, including water-based, solvent-based, and UV-curable formulations. Their versatility extends across multiple industries, from automotive and construction to textile and paper coatings. The spheres' controlled expansion process ensures consistent performance and reliable results, while their closed-cell structure contributes to excellent durability and weather resistance in the final coating application.