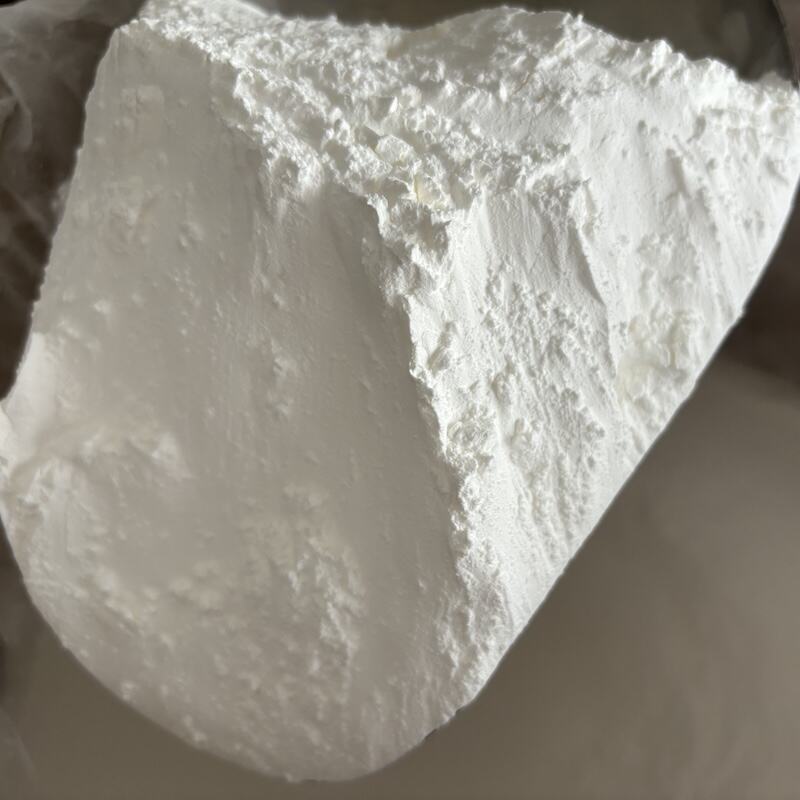

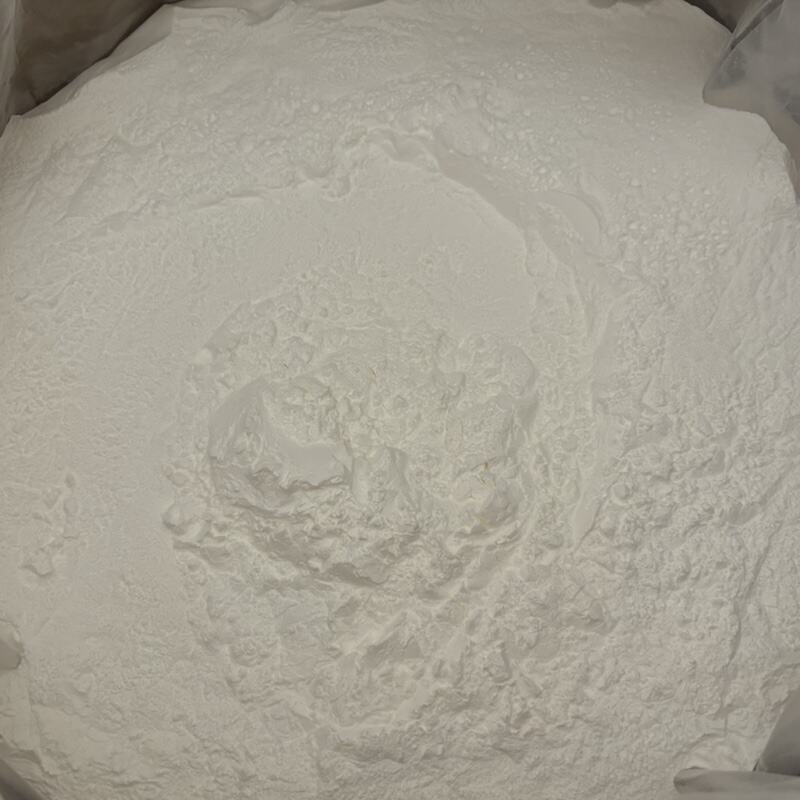

expandable microspheres for artificial leather

Expandable microspheres represent a groundbreaking innovation in artificial leather manufacturing, offering unprecedented control over material properties and performance. These microscopic particles consist of a thermoplastic shell encapsulating a hydrocarbon-based blowing agent, which expands when exposed to heat. In artificial leather production, these microspheres serve multiple crucial functions. When activated during the manufacturing process, they create a controlled cellular structure within the material, enhancing its physical properties and performance characteristics. The expansion process typically occurs at specific temperature ranges, allowing manufacturers to precisely control the final product's density, texture, and thermal insulation properties. These microspheres enable the production of lighter weight artificial leather while maintaining excellent durability and structural integrity. The technology has revolutionized the artificial leather industry by providing enhanced flexibility in design options, improved material performance, and increased cost-efficiency in production. The microspheres' unique expansion capabilities allow manufacturers to create artificial leather with varying degrees of softness, thickness, and thermal properties, making them suitable for diverse applications ranging from automotive upholstery to fashion accessories and furniture coverings.