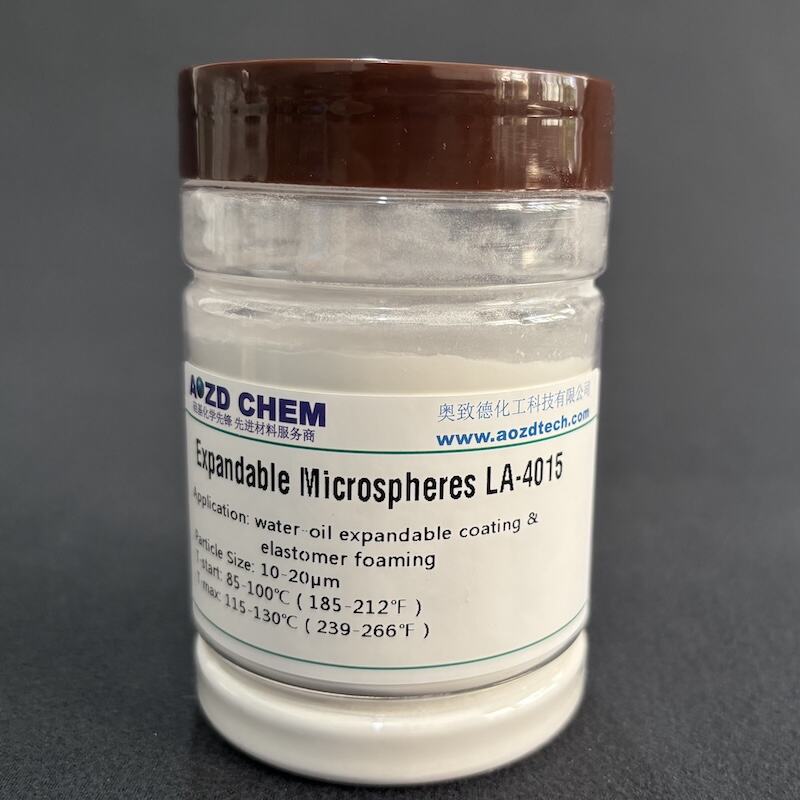

top rated expandable microspheres

Top rated expandable microspheres represent a revolutionary advancement in polymer technology, offering remarkable versatility and performance across various applications. These microscopic spheres consist of a thermoplastic shell encapsulating a liquid hydrocarbon, engineered to expand dramatically when exposed to heat. At their core, these microspheres undergo a controlled expansion process, typically increasing in volume by 40-60 times their original size when heated to specific temperatures. The technology behind these microspheres involves sophisticated polymer chemistry, resulting in products that maintain structural integrity while delivering precise expansion characteristics. Their applications span across multiple industries, from automotive manufacturing to construction materials. In automotive applications, they serve as lightweight filling agents, reducing vehicle weight while maintaining structural integrity. In construction, they enhance insulation properties and reduce material density. The microspheres also play a crucial role in the production of synthetic leather, providing texture and reducing weight. Their controlled expansion properties make them invaluable in sealants and adhesives, where they create consistent, reliable bonds while maintaining dimensional stability. The technology continues to evolve, with manufacturers developing new variants that offer enhanced temperature resistance, better expansion control, and improved compatibility with different matrix materials.