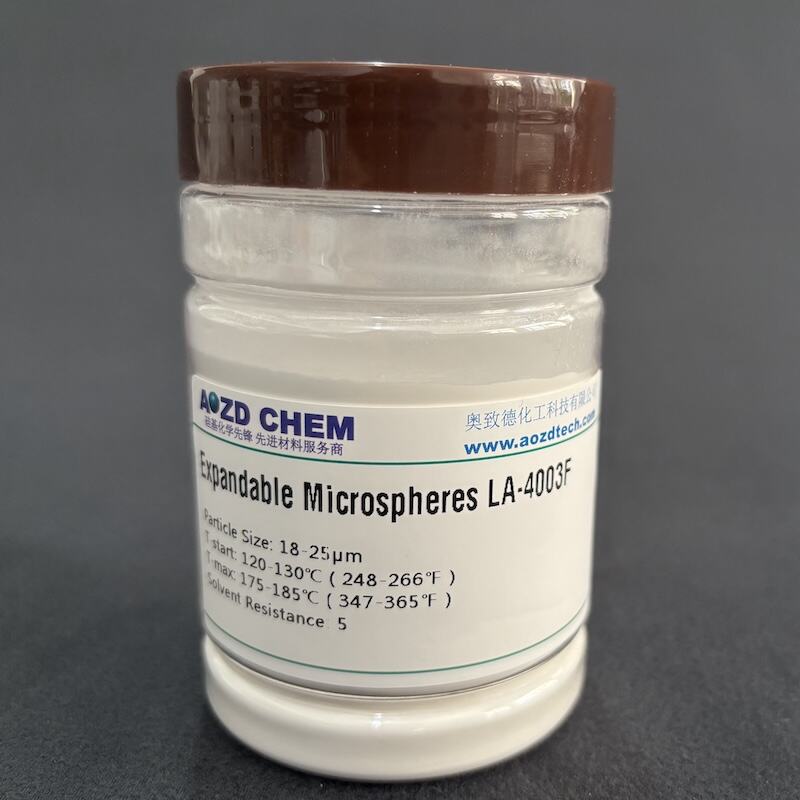

unexpanded microspheres

Unexpanded microspheres represent a groundbreaking advancement in materials science, consisting of thermoplastic shells encapsulating hydrocarbon-based blowing agents. These microscopic particles, typically ranging from 15 to 70 micrometers in diameter, remain inert at room temperature but undergo a remarkable transformation when exposed to heat. When heated to specific temperatures, the thermoplastic shell softens while the encapsulated hydrocarbon transitions to a gaseous state, causing the microspheres to expand dramatically, often increasing to 40-60 times their original volume. This unique property makes unexpanded microspheres invaluable in various industrial applications. The technology behind these microspheres allows for precise control over density reduction, thermal insulation, and structural modification in end products. They find extensive use in automotive components, construction materials, coatings, and specialty packaging solutions. The microspheres maintain their expanded form after cooling, creating stable, lightweight structures that contribute to significant weight reduction without compromising material integrity. Their controlled expansion characteristics enable manufacturers to achieve precise density specifications and uniform cell structures in foamed products, making them essential in modern manufacturing processes.