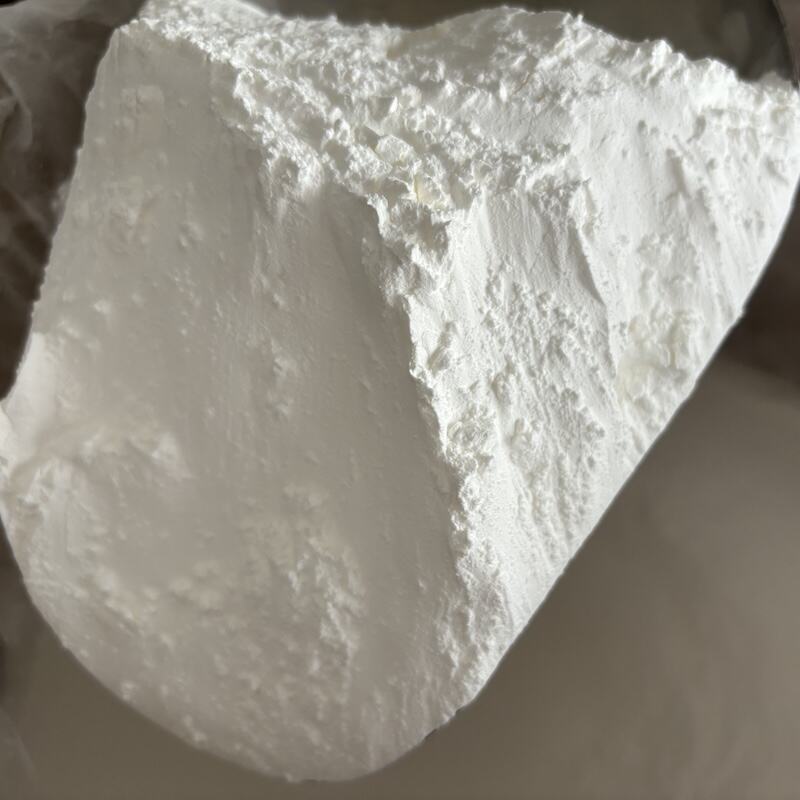

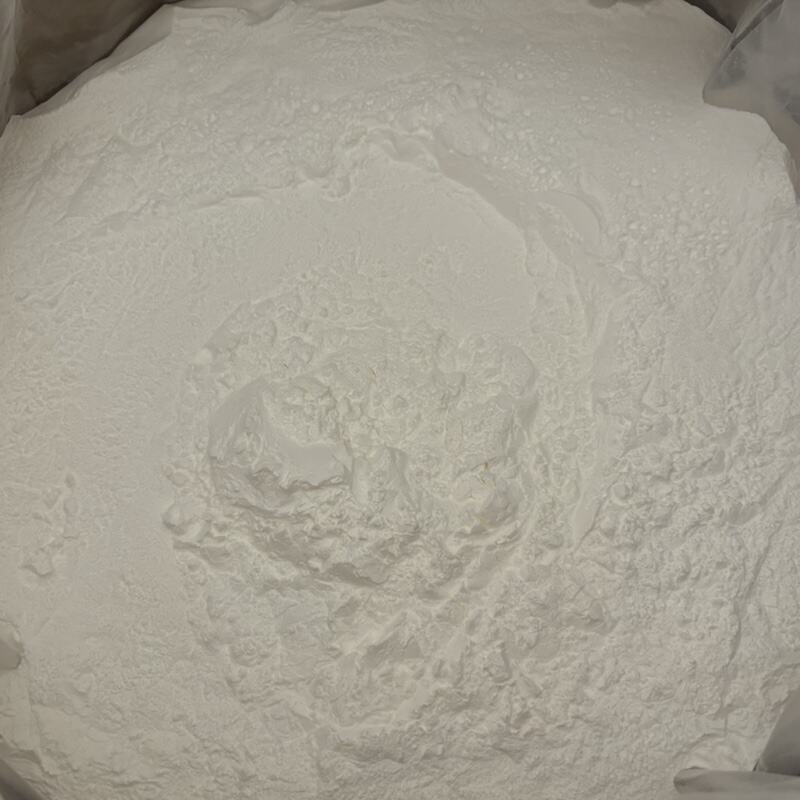

highperformance expandable microspheres

High-performance expandable microspheres represent a groundbreaking advancement in material science technology. These sophisticated particles consist of a thermoplastic shell encapsulating a hydrocarbon blowing agent, designed to expand significantly when exposed to heat. When activated at specific temperatures, these microspheres can expand up to 60 times their original volume, creating a unique combination of lightweight properties and structural integrity. The technology behind these microspheres allows for precise control over the expansion process, making them invaluable in various industrial applications. They serve as crucial components in automotive parts, construction materials, and advanced composites, where weight reduction and thermal insulation are essential. The microspheres' ability to maintain stability under varying conditions while providing consistent performance has revolutionized product development across multiple sectors. In manufacturing processes, these microspheres enable the creation of materials with reduced density, improved thermal properties, and enhanced acoustic characteristics. Their versatility extends to applications in packaging, sporting goods, and marine equipment, where they contribute to creating lighter, stronger, and more energy-efficient products. The controlled expansion process ensures uniform distribution of properties throughout the material, resulting in superior product quality and reliability.