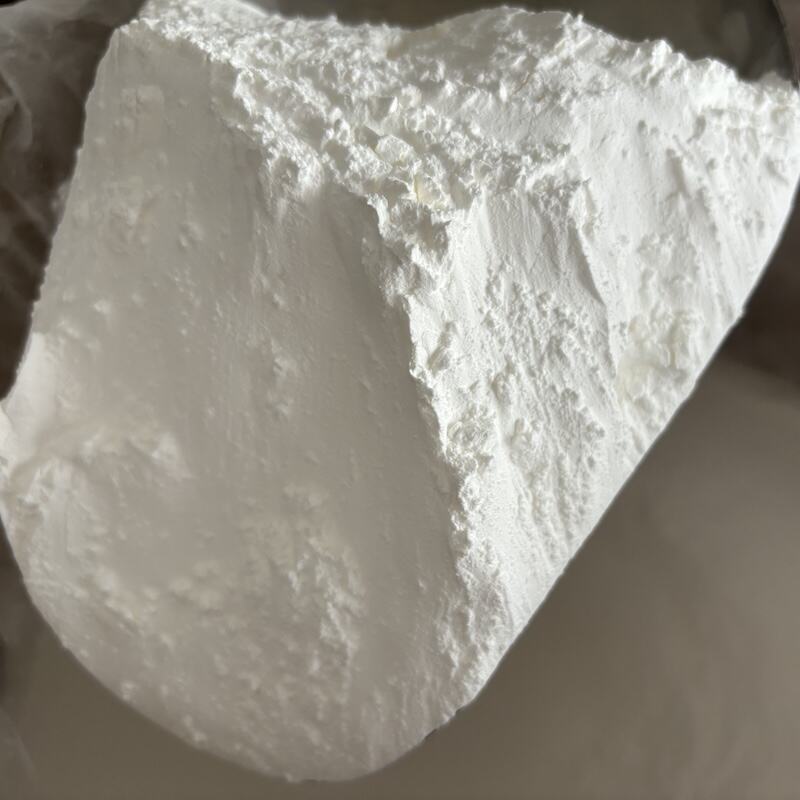

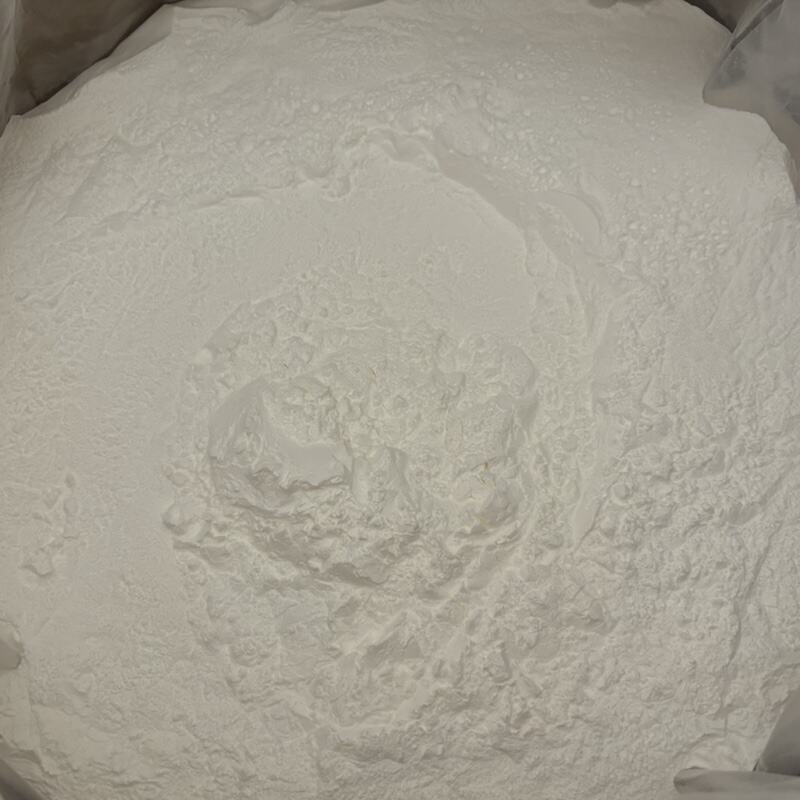

thermally expandable microspheres

Thermally expandable microspheres represent a revolutionary advancement in material science, consisting of tiny spherical particles with a thermoplastic shell encapsulating a hydrocarbon blowing agent. When exposed to heat, these microspheres undergo a remarkable transformation, expanding up to 40 times their original size while maintaining their spherical shape. This unique characteristic makes them invaluable in various industrial applications. The technology behind these microspheres involves precise engineering of the shell material and blowing agent, ensuring controlled expansion at specific temperature ranges. These microspheres function as lightweight fillers and blowing agents in numerous applications, from automotive parts to construction materials. Their expansion process is irreversible, creating stable, low-density structures that enhance product performance. The spheres' shell composition can be customized to achieve different expansion temperatures, typically ranging from 80°C to 200°C, making them versatile for various manufacturing processes. In industrial applications, these microspheres significantly reduce material density while maintaining or improving structural integrity, offering both weight reduction and cost savings. Their closed-cell structure provides excellent insulation properties, making them ideal for thermal and acoustic applications.