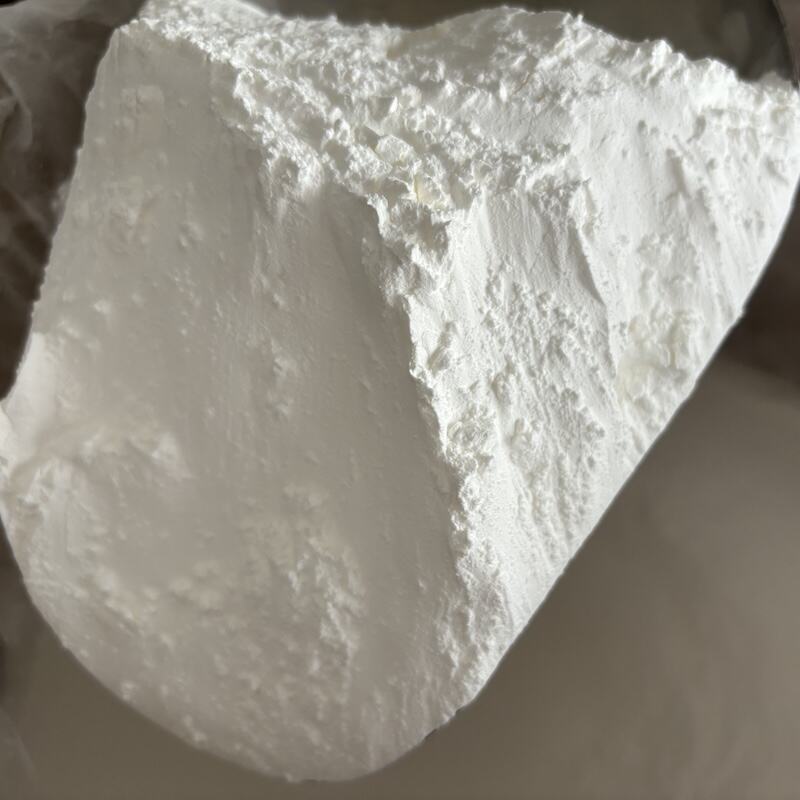

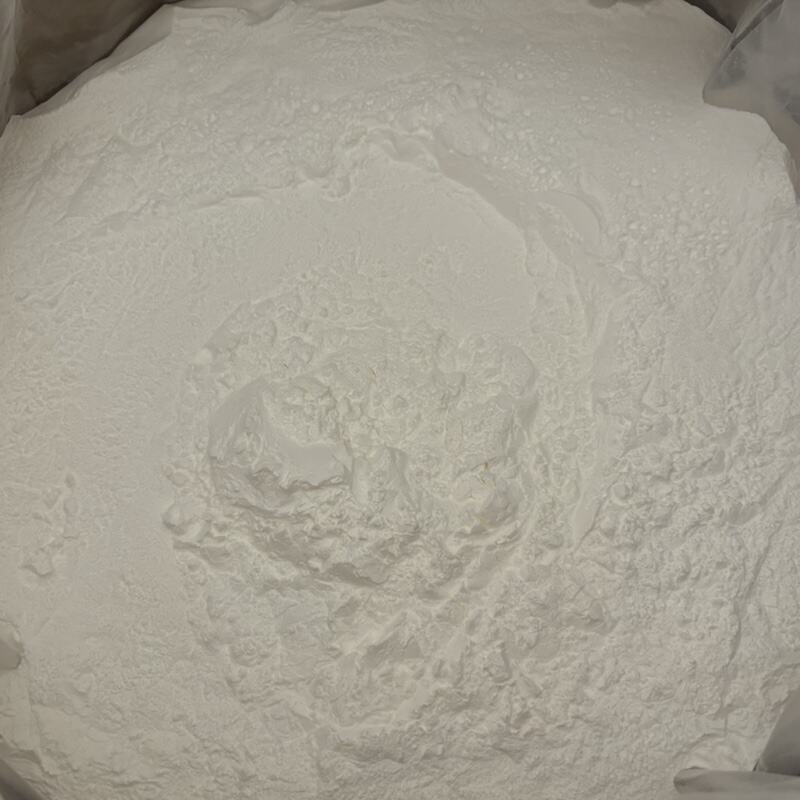

expandable microspheres manufacturer

An expandable microspheres manufacturer specializes in producing advanced polymer-based microspheres that expand when exposed to heat. These sophisticated facilities utilize cutting-edge technology to create microscopic spheres containing hydrocarbon gas encapsulated within a thermoplastic shell. When heated, these spheres can expand up to 40 times their original size while maintaining structural integrity. The manufacturing process involves precise control of particle size distribution, shell composition, and expansion characteristics to meet diverse industry requirements. Modern manufacturers employ automated production lines equipped with advanced quality control systems to ensure consistent product quality. These facilities typically feature state-of-the-art research and development laboratories for continuous product innovation and customization capabilities. The manufacturing process incorporates environmental controls and safety measures to maintain product purity and worker safety. Many manufacturers also offer technical support services, helping customers optimize microsphere application in their specific processes. These facilities often maintain ISO certifications and comply with international quality standards, ensuring their products meet global market requirements. The production capabilities typically range from small-scale batches for specialized applications to large-volume production for industrial users, with the ability to modify microsphere characteristics such as particle size, expansion temperature, and shell composition according to customer specifications.