expandable microspheres for automotive

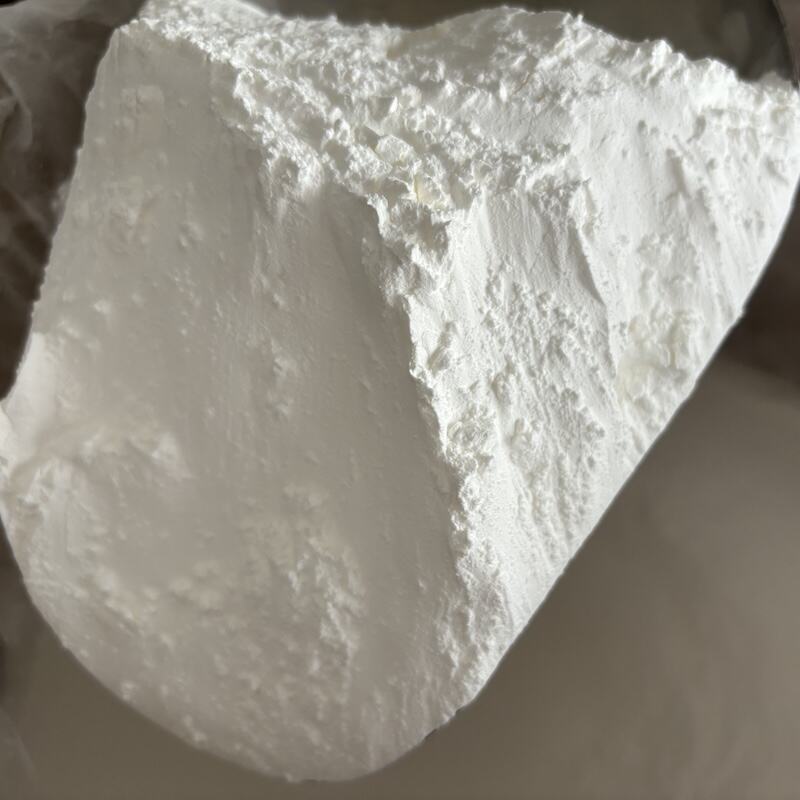

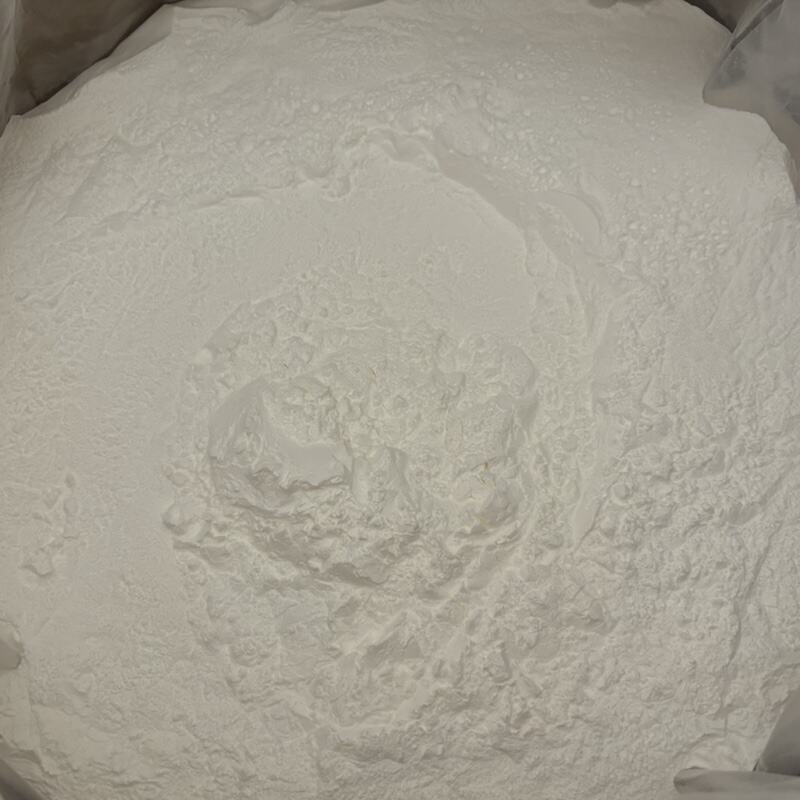

Expandable microspheres for automotive applications represent a groundbreaking advancement in vehicle manufacturing technology. These innovative materials consist of thermoplastic shells containing hydrocarbon-based blowing agents that expand when exposed to heat. When activated, these microspheres can increase in size up to 40 times their original volume, creating lightweight, strong structures ideal for automotive applications. The technology serves multiple functions in modern vehicle production, including weight reduction, noise dampening, and structural reinforcement. These microspheres are particularly valuable in producing lightweight composite materials, which help automotive manufacturers meet increasingly stringent fuel efficiency standards while maintaining vehicle safety and performance. The microspheres can be incorporated into various automotive components, including door panels, dashboard materials, underbody shields, and acoustic insulation systems. Their controlled expansion properties allow for precise material density control, enabling manufacturers to optimize component design for specific performance requirements. The technology also contributes to improved vehicle acoustics by creating effective sound-dampening barriers within vehicle structures. Additionally, these microspheres enhance the processing efficiency of automotive parts production, reducing cycle times and energy consumption during manufacturing.