silicone emulsion factory

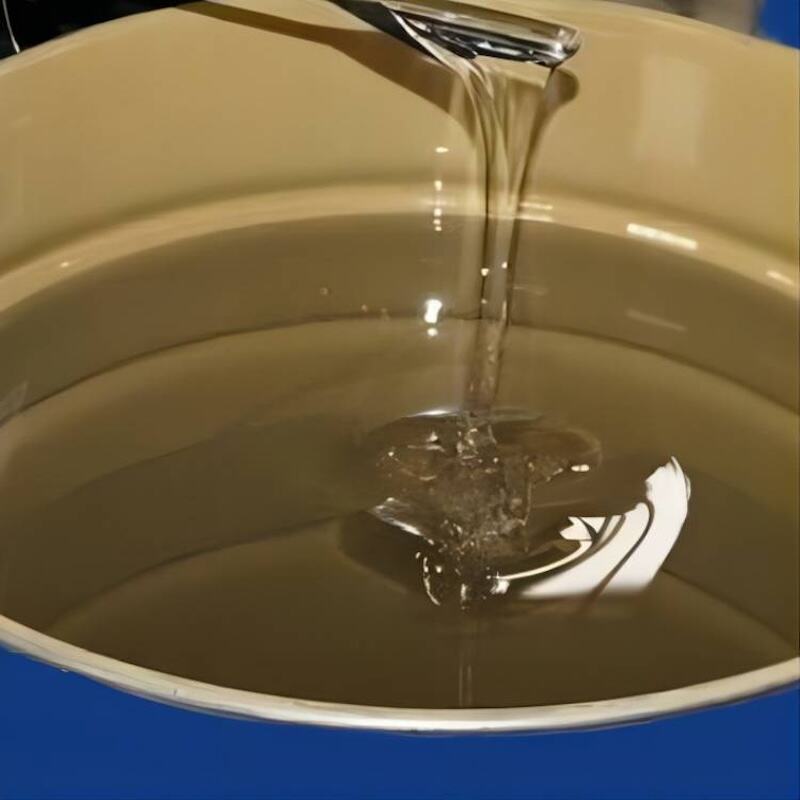

A silicone emulsion factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality silicone-based emulsions for various industrial applications. These facilities combine advanced processing equipment, precise control systems, and innovative production techniques to create stable silicone emulsions. The factory typically features multiple production lines equipped with high-shear mixers, temperature-controlled reactors, and sophisticated quality control laboratories. The manufacturing process involves the careful blending of silicone polymers with water and specialized emulsifiers using proprietary technologies. Modern silicone emulsion factories incorporate automated systems for raw material handling, process control, and product testing, ensuring consistent quality and efficiency. The facility also maintains strict environmental controls and clean room conditions where necessary. Quality assurance protocols include in-process testing, final product analysis, and comprehensive documentation systems. The factory's capabilities extend to producing various types of silicone emulsions, including micro-emulsions, macro-emulsions, and specialized formulations for specific applications. These products serve diverse industries, including textiles, personal care, construction, and automotive sectors. The facility also typically includes research and development capabilities for custom formulation development and product optimization.