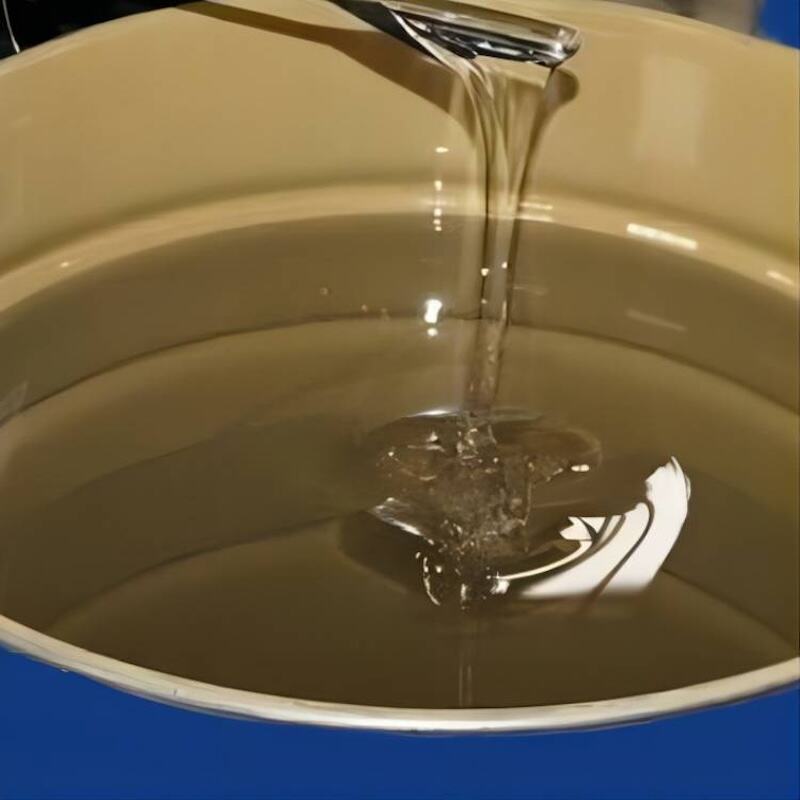

dimethyl silicone oil

Dimethyl silicone oil is a versatile synthetic fluid renowned for its exceptional stability and performance across various applications. This clear, colorless liquid comprises a backbone of alternating silicon and oxygen atoms, with methyl groups attached to silicon. Its molecular structure grants it remarkable thermal stability, maintaining consistent properties across a wide temperature range from -50°C to 200°C. The oil exhibits outstanding water repellency, excellent dielectric properties, and low surface tension, making it invaluable in numerous industrial processes. Key characteristics include chemical inertness, low volatility, and resistance to oxidation, which contribute to its long service life. In industrial applications, it serves as a heat transfer medium, lubricant, and release agent. The cosmetic and personal care industries utilize it as an essential ingredient in formulations due to its smooth feel and skin-friendly properties. Additionally, its application extends to electronics manufacturing, where it functions as a protective coating and cooling medium. The oil's viscosity can be precisely controlled during manufacturing, allowing for customization to specific application requirements.