silicone fluid manufacturer

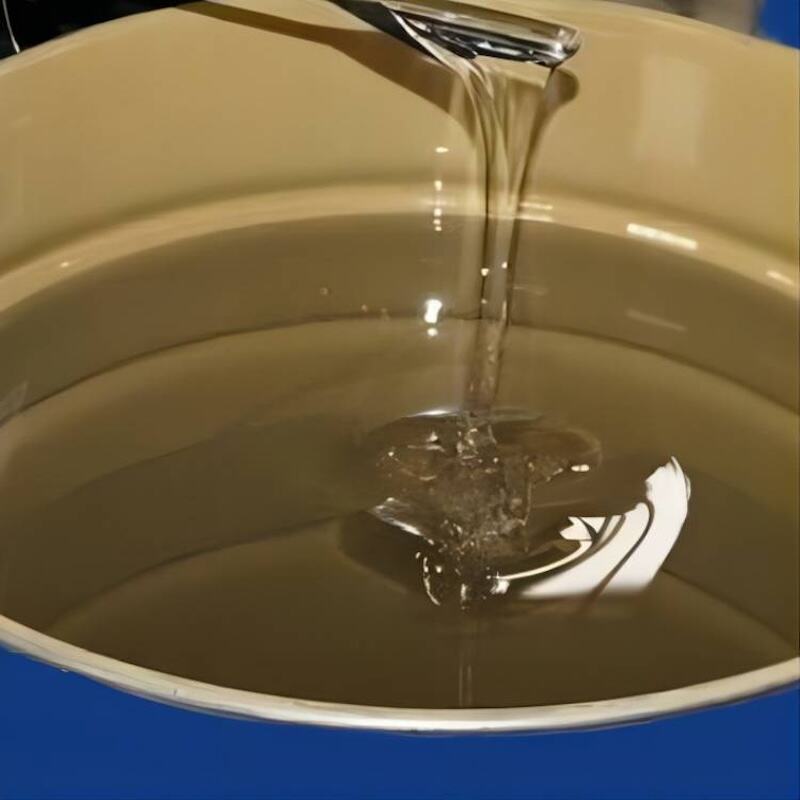

A silicone fluid manufacturer specializes in developing and producing high-quality silicone-based fluids that serve various industrial and commercial applications. These manufacturers employ advanced production technologies and rigorous quality control measures to create versatile silicone fluids with precise specifications. Their facilities typically feature state-of-the-art processing equipment capable of producing silicone fluids with varying viscosities, ranging from ultra-low to high viscosity grades. The manufacturing process involves careful selection of raw materials, precise polymerization control, and sophisticated purification techniques to ensure product consistency and purity. These manufacturers often maintain extensive research and development departments dedicated to innovating new formulations and improving existing products to meet evolving market demands. They serve diverse industries including automotive, personal care, electronics, construction, and medical devices. The production facilities are typically equipped with advanced testing laboratories that conduct comprehensive quality assessments, ensuring each batch meets stringent industry standards and customer specifications. Many manufacturers also offer customization services, allowing clients to request specific modifications to standard formulations to suit their unique applications.