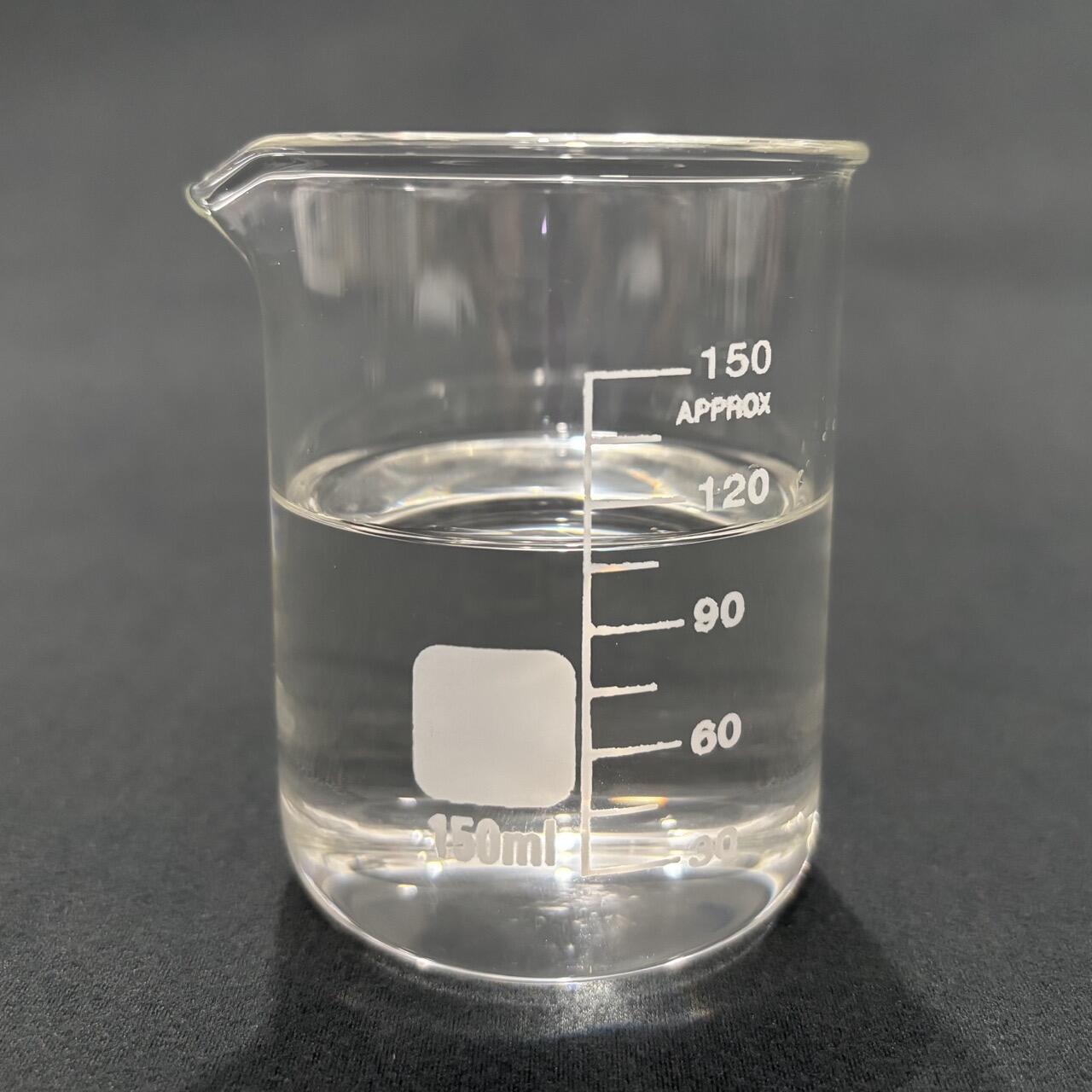

highperformance silicone dispersion

High-performance silicone dispersion represents a cutting-edge material solution that combines advanced silicone technology with superior dispersibility characteristics. This innovative formulation consists of finely dispersed silicone particles suspended in a carefully balanced aqueous medium, ensuring optimal stability and performance. The product delivers exceptional surface modification properties, making it ideal for applications requiring water repellency, enhanced durability, and improved surface characteristics. The dispersion's unique composition allows for easy integration into various manufacturing processes, providing uniform coverage and consistent results across different substrate materials. Its advanced formulation ensures excellent adhesion properties while maintaining flexibility and weather resistance. The technology behind this dispersion enables it to create an ultra-thin, transparent protective layer that doesn't alter the substrate's appearance while providing superior protection against environmental factors. The product's versatility makes it suitable for various industries, including textiles, construction materials, and industrial coatings, where it can be applied through conventional methods such as spraying, dipping, or padding. The dispersion's stability ensures extended shelf life and maintains its performance characteristics over time, making it a reliable choice for long-term applications.