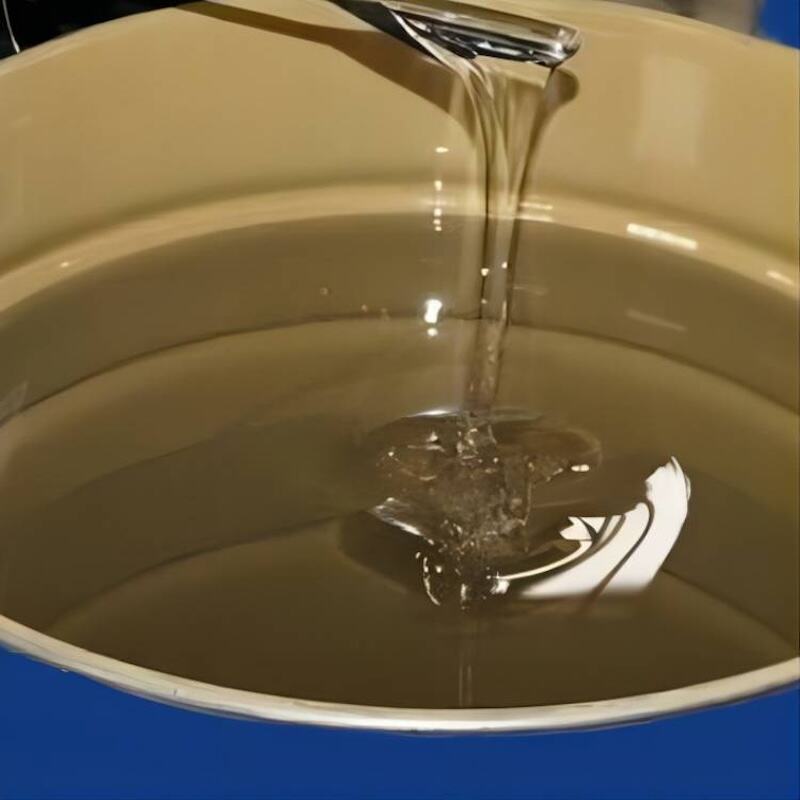

silicone emulsion made in china

Silicone emulsion made in China represents a cutting-edge solution in the industrial chemical sector, offering exceptional performance and versatility. This advanced formulation combines high-quality silicone materials with innovative emulsification technology, resulting in a stable, water-based product that delivers superior performance across multiple applications. The emulsion features carefully controlled particle sizes and outstanding stability, ensuring consistent performance in various environmental conditions. These products are manufactured using state-of-the-art equipment and stringent quality control processes, meeting international standards while maintaining cost-effectiveness. The emulsion demonstrates excellent spreadability and compatibility with various substrates, making it ideal for applications in textile treatment, personal care products, and industrial processing. Its water-based nature makes it environmentally friendly and easy to handle, while still providing the characteristic benefits of silicone, such as water repellency, softness, and durability. The manufacturing process incorporates advanced quality control measures, ensuring batch-to-batch consistency and reliable performance. Chinese manufacturers have significantly invested in research and development, resulting in products that compete effectively in the global market while offering exceptional value.