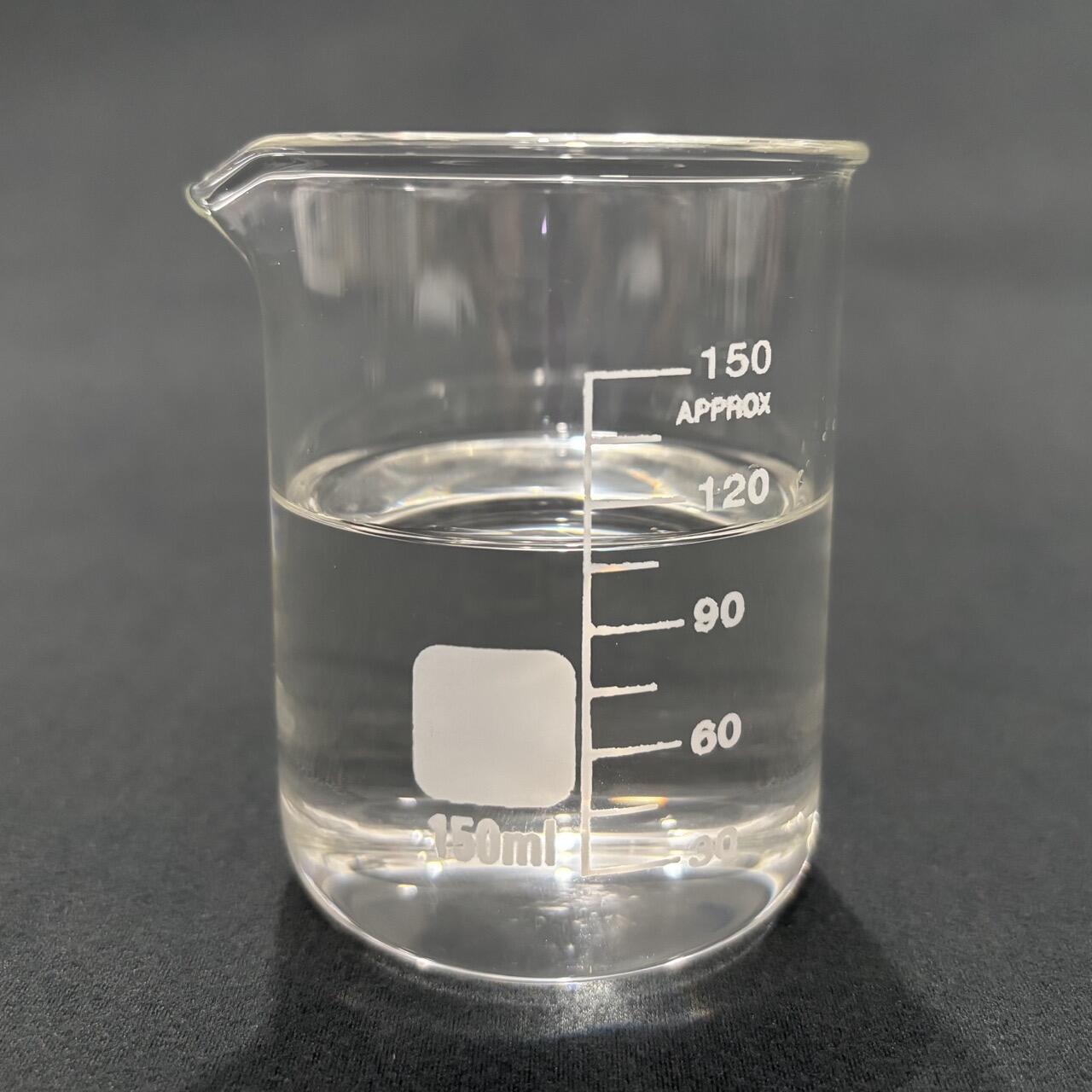

silicone fluid factory

A silicone fluid factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality silicone-based fluids for various industrial applications. The facility encompasses advanced processing units, quality control laboratories, and automated production lines that ensure consistent product quality. The factory utilizes cutting-edge polymerization technology to synthesize silicone fluids with precisely controlled molecular weights and viscosities. Key production areas include raw material handling systems, reaction vessels equipped with precise temperature and pressure controls, and sophisticated filtration systems. The facility also features specialized blending units for customizing silicone fluid formulations according to specific customer requirements. Environmental control systems maintain optimal conditions for production while ensuring compliance with environmental regulations. Quality assurance laboratories conduct continuous testing throughout the production process, employing advanced analytical instruments to verify product specifications. The factory's automation systems enable real-time monitoring of production parameters and facilitate quick adjustments to maintain product consistency. Storage facilities are equipped with temperature-controlled tanks and advanced inventory management systems to ensure product stability and efficient distribution. The facility's design incorporates safety features including fire suppression systems, emergency shutdown capabilities, and proper ventilation to maintain a secure working environment.