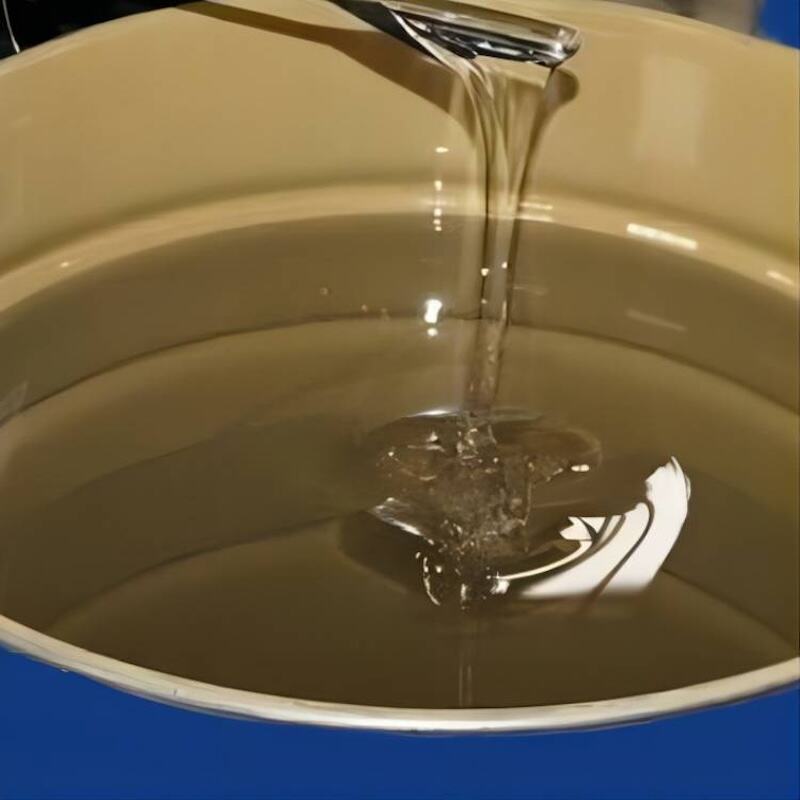

dc200 silicone oil

DC200 silicone oil is a versatile and high-performance polysiloxane fluid that has become indispensable in various industrial and commercial applications. This remarkable fluid offers exceptional thermal stability, maintaining its properties across a wide temperature range from -40°C to 200°C. As a dimethyl silicone fluid, DC200 demonstrates outstanding water repellency, excellent dielectric properties, and remarkable chemical inertness. The product is available in various viscosities, typically ranging from 0.65 to 100,000 centistokes, allowing users to select the perfect grade for their specific applications. DC200 silicone oil exhibits low surface tension, making it an excellent spreading and wetting agent. Its non-toxic nature and compatibility with many materials have made it a preferred choice in industries ranging from personal care to industrial manufacturing. The oil's exceptional lubricating properties, coupled with its resistance to oxidation and thermal degradation, ensure long-lasting performance in demanding environments. Whether used as a heat transfer fluid, lubricant, anti-foaming agent, or release agent, DC200 silicone oil consistently delivers reliable performance while maintaining its chemical and physical properties.