silicone dispersion factory

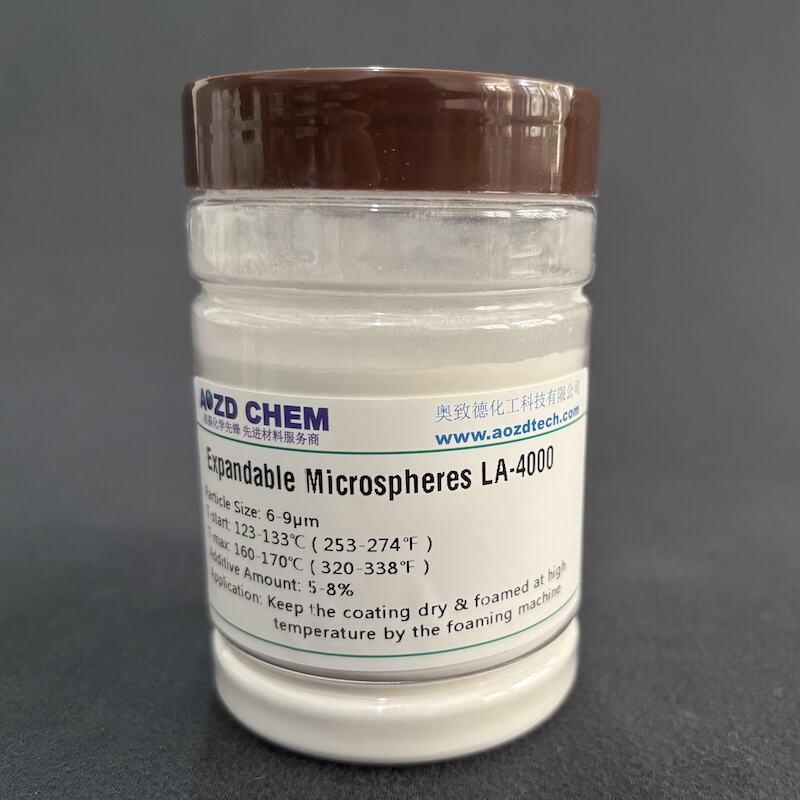

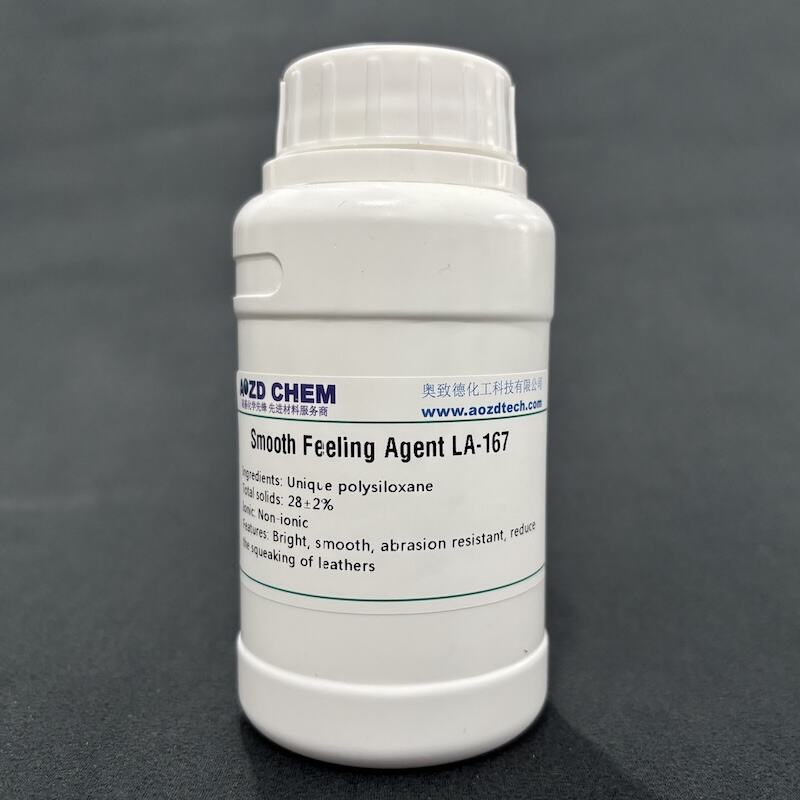

A silicone dispersion factory represents a cutting-edge manufacturing facility dedicated to producing high-quality silicone dispersions through advanced processing techniques. These facilities integrate state-of-the-art equipment and precise control systems to create stable, uniform silicone dispersions used across various industries. The factory's core operations include raw material preparation, mixing and homogenization, quality control testing, and packaging systems. Advanced dispersing equipment enables the creation of fine particle distributions, ensuring product consistency and performance. The facility employs automated process control systems that monitor and adjust parameters such as temperature, pressure, and mixing speeds in real-time. Environmental control systems maintain clean room conditions where necessary, while sophisticated filtration systems ensure product purity. Quality assurance laboratories within the facility conduct comprehensive testing of physical properties, particle size distribution, and stability characteristics. The factory typically incorporates modern storage solutions with temperature-controlled environments for both raw materials and finished products. Material handling systems are designed to minimize contamination risks and maintain product integrity throughout the manufacturing process. These facilities often feature flexible production lines capable of manufacturing various grades of silicone dispersions to meet diverse customer specifications and applications, from cosmetics to industrial coatings.